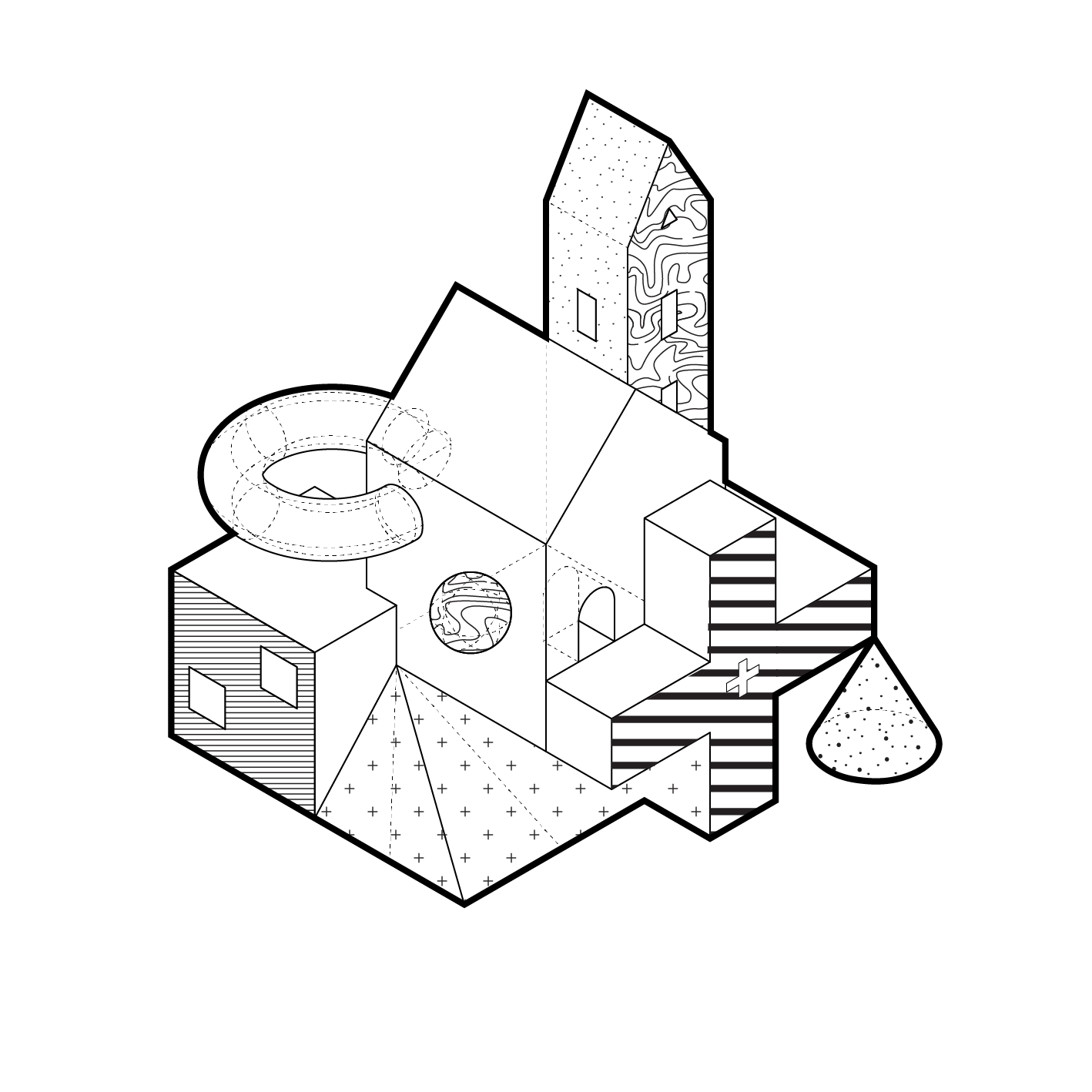

The complexity of the Bangkok container terminal’s operation both in its logistic and strategic, make the container terminal the function in the precise choreography.

Bangkok port is under the Port Authority of Thailand (PAT) is a state corporation of Thailand, responsible for the regulation and governance of the ports of Thailand.Bangkok Port is located on the left side of the Chao PhrayaRiver between km.+26.5 and km.+28.5 Klongtoey District, Bangkok. It is well connected with road and rail systems, which help transport of cargoes between the port and its hinterland fast and economical.

The port has the total 3803091.89 sqm2 inland area and 66 kilometers long offshore area. The water level is only between -8m to -11m, therefor big cargo vessel could not access to Bangkok port.

Bangkok port has 14 Ship to shore cranes, 34 Rubbered Gantry cranes, 35 Reachstacker cranes, 25 empty container handlers, 154 Container Trucks provided.The Port not only of the containers, but also providing a warehouse and logistic services.

The choreography of discharge/loading/handling containers has to be systematic, precise, and fast in order for the port to earn the maximum profit. Each day delays could caused tremendous of money loss. The study focused at the Bangkok port as the case studies.The study will focus at Bangkok Port at the Vessel Berthing 1 area.

Scenario:

1 a cargo vessel came in to the port

2. Two ship-to-shore cranes (STS) will be used in the process. Dual cycle will be use to discharge and load containers at the same time.(The reachstacker will help bring containers for loading in this process)

3 There will be two trucks waiting for their containers.

One truck would immediately delivery its goods to its customers. The later truck would bring the container to the stacking area, where the rubber gantry will stack the containers.

This drawing is also shown the ‘Dual-cycle system’ In traditional ship dispatching there are many empty trips, because ships are first discharged and then loaded. Simply put, a container gantry crane first lifts a container from the ship and then puts it on land on an automated transporter (AGV) that brings the container to the storage block. Then the container gantry crane moves back to the ship without load to discharge the next container.

With the Dual Cycle the unnecessary empty trips are omitted. Because after putting the container on the AGV on land, the crane on its way back to the ship picks up another container that is loaded onto the ship.

CREDITS

–